SLA breaches in UK 3PL operations rarely come from a single major failure. They usually begin with small, routine issues that compound under pressure.

A delayed inbound delivery,inventory not made live before a 2pm cut-off, or an order held back during a busy shift because a system did not flag urgency.By the time the issue is visible in a report or raised by a client, the SLA is already broken.

In today’s UK fulfilment environment, margins are tighter, labour is harder to secure, and client expectations are rising. Next-day delivery is no longer a differentiator, it is assumed.

At the same time, 3PLs are managing more clients, more channels, and more carrier visibility than ever before. Keeping SLAs intact often feels like process control and more like constant firefighting.

This is why automation is becoming critical for UK 3PLs. When applied correctly, automation does not replace people. It removes silent operational risk before it turns into missed SLAs, service credits, and damaged client trust.

Why SLA Breaches Are a Growing Concern for UK 3PLs

Service Level Agreements (SLAs) define the commercial relationship between UK 3PLs and their clients. Meeting them consistently is becoming harder, not because teams are under performing, but because the operating environment is becoming more volatile.

Most SLAs focus on visible, time-bound metrics:

- Dispatch speed: Meeting strict daily cut-off times (e.g. 2pm)

- Delivery promises: Hitting carrier targets (Next Day vs Standard)

- Order accuracy: Zero error rates in picking and labelling

- Response times: Resolving client queries quickly

On paper, these metrics look manageable. In practice, they are increasingly exposed to upstream delays, system blind spots, and carrier performance variability. As volume grows, even minor inefficiencies can cascade into SLA failures across multiple clients at once.

The Hidden Causes of Failure

In reality, many SLA breaches occur long before picking and packing begins.

- Dock-to-stock delays are one of the most common contributors. Inbound deliveries may arrive on time, but slow receiving, manual checks, or limited inbound capacity can delay stock availability. When inventory is not made live quickly, outbound orders queue silently, putting dispatch SLAs at risk before the warehouse floor feels busy.

- Returns bottlenecks are another frequent issue. During peak periods, returns are often deprioritised in favour of outbound volume. Inspections, restocking, and refunds slow down, breaching SLAs tied to reverse logistics and damaging the end-customer experience for merchants.

These issues are rarely caused by lack of effort. They stem from processes that rely too heavily on manual oversight and delayed visibility.

The Business Impact

SLA breaches carry a direct and measurable cost. . Penalties, service credits, and refunds erode already thin margins.Over time, repeated failures weaken client confidence, and increase churn risk.

More importantly, inconsistent SLA performance limits growth. Merchants become hesitant to scale volume, onboard new channels, or commit to longer-term contracts when fulfilment reliability feels uncertain. In this context, proactive SLA management becomes a core retention and growth strategy, not just an operational concern.

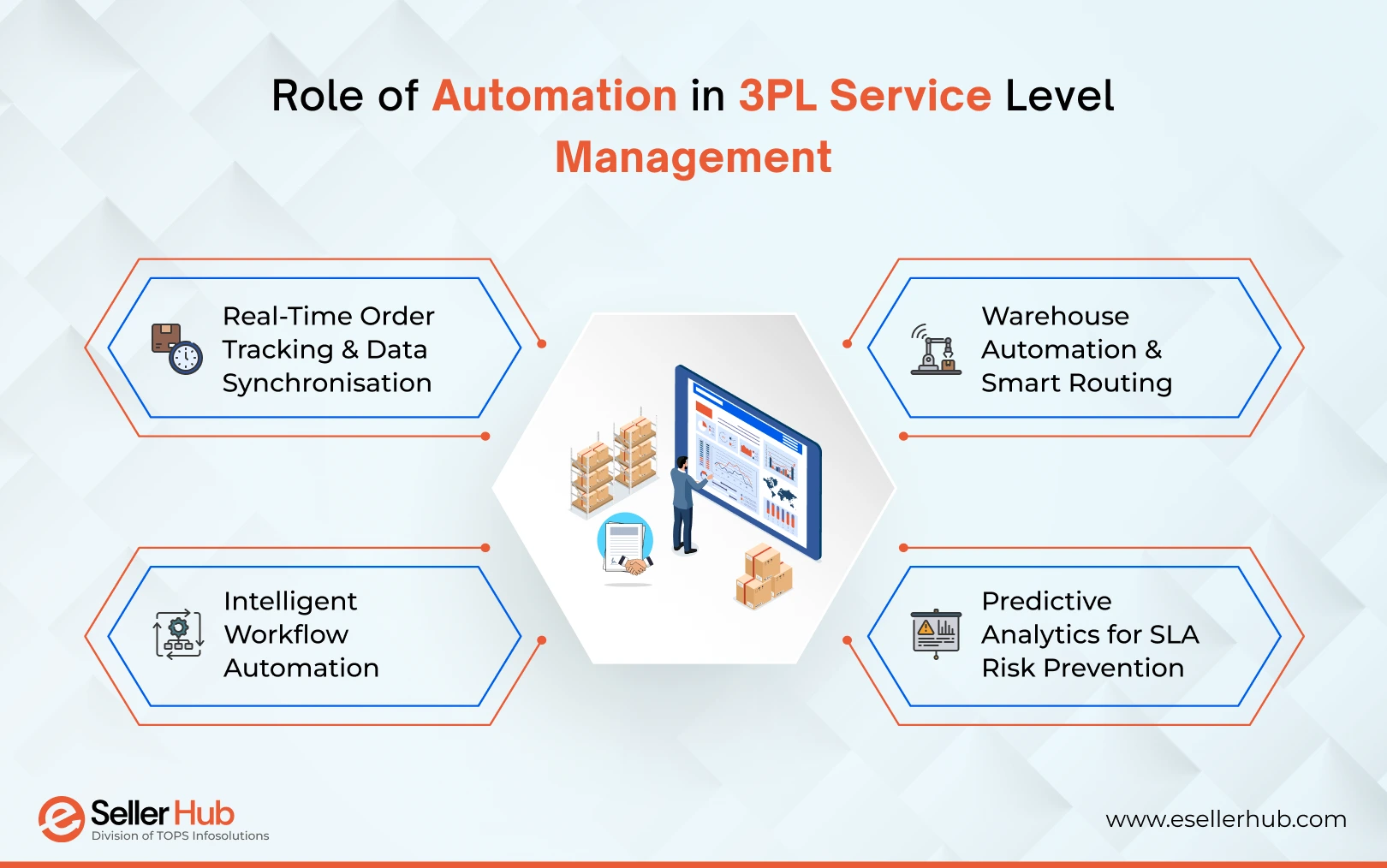

The Role of Automation in SLA Compliance

Automation helps UK 3PLs to shift from reactive firefighting to proactive control. Instead of identifying issues after a breach, automated systems surface risks early, keeping operations aligned with client promises.

When automation is applied to the right parts of the fulfilment lifecycle, it removes reliance on human memory, manual checks, and delayed reporting. This creates consistency across clients, shifts, and peak periods.

1. Real-Time Order Tracking and Data Synchronisation

Many SLA breaches originate in disconnected systems, such as orders stuck in a pending state or inventory not syncing in time. Automation resolves this by unifying order visibility across all clients and sales channels in real time.

With automated synchronisation:

- Prevent missed cut-offs: Orders approaching the 2 pm dispatch deadline are flagged automatically.

- Eliminate “ghost” inventory: Stock levels sync in real time to prevent overselling.

- Proactive alerts: Managers are notified immediately if an order stalls, allowing intervention before the SLA is broken.

This visibility is especially critical during peak periods, when legacy tracking methods break down and SLA risks escalate quickly.

2. Intelligent Workflow Automation

Relying on manual decision-making for every order creates bottlenecks, especially under pressure. Intelligent workflow automation removes the guesswork by auto-assigning tasks based on logic and SLA urgency, not just availability.

This ensures that the most time-sensitive orders are always addressed first, without requiring constant supervision or escalation.

- SLA-prioritised picking: Orders with the tightest deadlines, such as Next Day Delivery, are automatically prioritised over standard shipments, ensuring urgent orders are picked first.

- System-guided accuracy: Handheld scanners guide pickers to the correct location and verify items on scan. This built-in error-proofing protects order accuracy SLAs by preventing the wrong item from being packed.

- Auto-assignment: Tasks are routed to the nearest available operative within a zone, reducing travel time and speeding up the fulfilment cycle.

This approach is particularly valuable during peak seasons. By simplifying workflows for temporary staff, 3PLs can maintain speed and accuracy without constant manual oversight.

3. Warehouse Automation and Smart Routing

Warehouse automation removes the manual friction that causes fulfilment delays. By streamlining both inbound and outbound processes, 3PLs can protect SLAs even when volumes spike.

A critical but often overlooked area is dock-to-stock automation. Automated inbound workflows accelerate receiving, verification and putaway, ensuring products are live and available for sale in hours, not days. This eliminates “dead inventory” backlogs that threaten dispatch SLAs before picking even begins.

Automation also improves delivery reliability through smart carrier routing. Instead of guesswork, the system automatically selects the best carrier for each shipment (Royal Mail, DPD, or Evri) based on:

- Delivery promise: Ensuring the required service level (e.g. Next Day) is met

- Cost efficiency: Choosing the lowest-cost carrier that still guarantees the SLA (least-cost routing)

- Live performance: Avoiding carriers experiencing known network delays

By aligning internal warehouse workflows with real-time carrier performance, 3PLs can protect delivery promises while keeping shipping margins under control.

4. Predictive Analytics for SLA Risk Prevention

Even with efficient workflows in place, blind spots remain. Predictive analytics moves SLA management from reacting to today’s failures to preventing tomorrow’s ones.

By analysing historical order, inventory and carrier data, , systems can identify patterns that consistently lead to SLA breaches, such as specific SKUsthat slowpacking or recurring carrier delays in certain postcodes.

With these insights, 3PL managers can:

- Forecast staffing needs: Predict labour requirements for upcoming peaks, avoiding understaffing that leads to dispatch failures.

- Identify high-risk clients: Spot client accounts that consistently push SLAs to the limit, enabling contract renegotiation or process adjustments.

- Pre-empt carrier issues: Shift volume away from struggling carriers before packages get stuck in their networks.

Instead of waiting for an “SLA missed” alert, teams can adjust labour, inventory, and carrier allocation in advance. This data-driven approach turns SLA compliance from a daily struggle into a predictable standard.

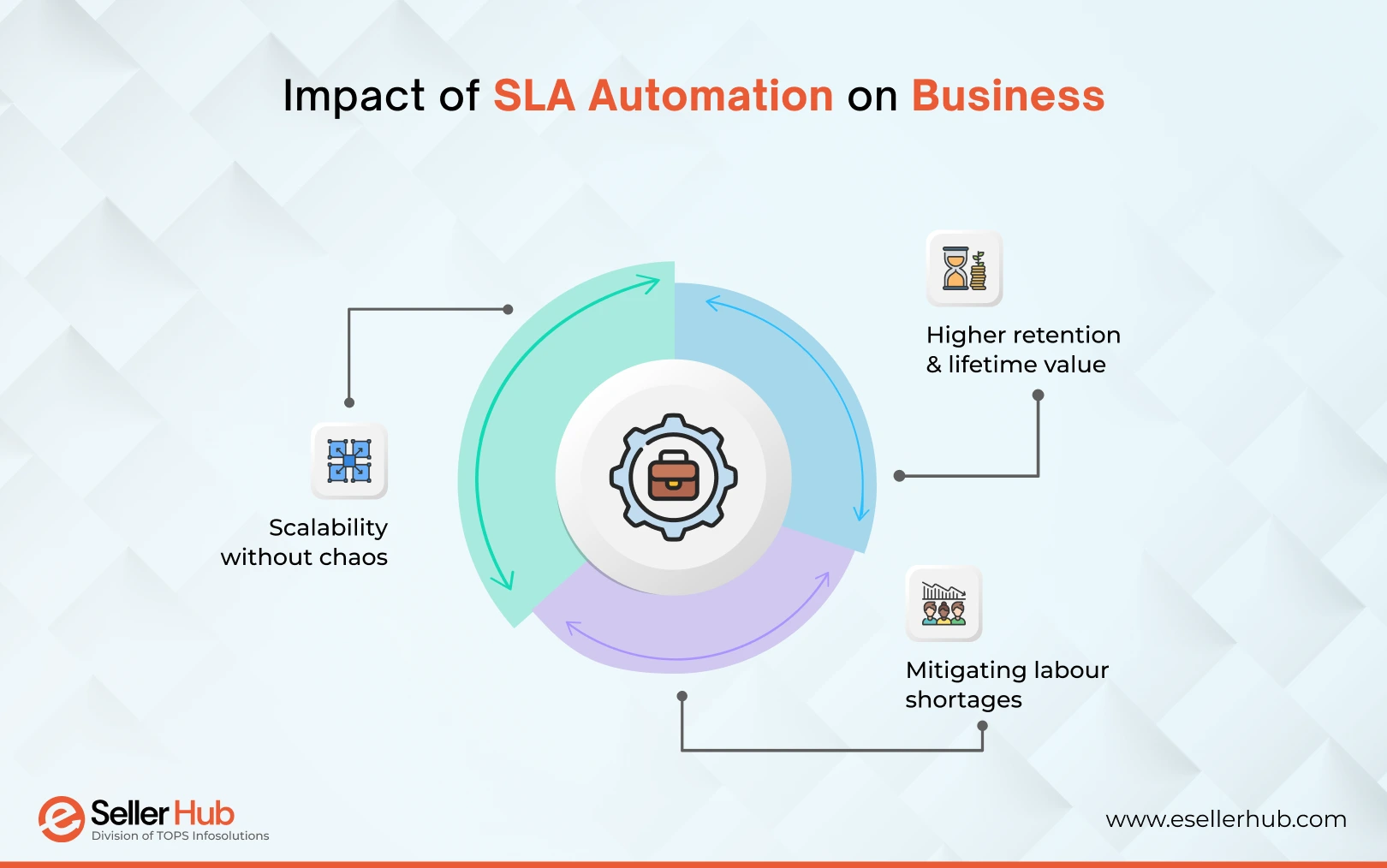

The Business Impact of Automating SLA Management

The business impact of SLA automation is most visible during periods of pressure, when margins, staffing, and service levels are all tested at once. Its real value, however, lies in long-term profitability and resilience. By eliminating process-driven errors and enforcing consistency, UK 3PLs can meet client expectations without scaling headcount in line with volume.

The impact is measurable across three key areas:

Scalability without chaos

During Q4, Black Friday, or promotional spikes, automated workflows absorb significantly higher order volumes without degrading performance. This stability is often the difference between a profitable peak season and an operational meltdown that damages client relationships

Mitigating labour shortages

With ongoing staffing challenges across the UK logistics sector, automation enables 3PLs to do more with leaner teams. Standardised, system-guided workflows reduce reliance on expensive temporary agency labour and help maintain accuracy and consistency when onboarding staff at speed.

Higher retention and lifetime value

Consistent SLA performance is one of the strongest retention drivers in fulfilment. When merchants trust you to deliver their brand promise reliably, they stay longer, refer others, and become less price-sensitive.

Ultimately, automation allows SLA compliance to scale reliably as operations grow, without turning every increase in volume into a stress test.

How eSellerHub Helps UK 3PLs Stay Ahead

eSellerHub provides modular backend systems designed around the reality of UK 3PL operations. Orders, inventory, warehouse activity, and carrier data are unified into a single real-time view, giving operators a unified view of SLA performance across all clients.

Rather than forcing 3PLs into rigid workflows, eSellerHub adapts to existing warehouse layouts, client requirements, and carrier strategies. This flexibility is essential in multi-client, multi-warehouse environments where one-size-fits-all systems often fall short.

Client portals provide merchants with transparent access to fulfilment performance, reducing support overhead and strengthening trust without increasing operational burden.

The Future of SLA Management in the UK 3PL Industry

SLA management in the UK 3PL sector is moving beyond basic reporting and manual oversight. Competitive advantage is increasingly driven by real-time visibility, automation, and predictive control, rather than reactive fixes after issues have already occurred.

As client expectations continue to rise, SLAs are expanding to cover the full fulfilment lifecycle, including inbound processing, outbound delivery, and reverse logistics. 3PLs that continue to rely on manual processes will find it harder to keep pace, particularly during peak periods and ongoing labour shortages.

Predictive control is emerging as a defining capability in modern SLA management. Providers that invest early will be better positioned to deliver consistent reliability, protect margins, and build long-term client trust in an increasingly demanding market.

Conclusion

Reliable SLA performance is the foundation of a successful UK 3PL. As client expectations rise and operational pressure increases, manual processes and delayed visibility are no longer efficient.

Automation enables consistent SLA compliance without linear increases in headcount. It removes silent risk from the fulfilment lifecycle, protects margins, and allows operations to scale calmly rather than reactively.