A Service Level Agreement, or SLA, defines what a 3PL is expected to deliver and how fulfilment performance is measured. In a 3PL service level agreement, this usually covers accuracy, dispatch timelines, returns handling, and system reliability across day-to-day operations.

For UK ecommerce businesses working with a 3PL service provider in the UK, SLAs have become more important as customer expectations tighten and fulfilment operations grow more complex. Missed dispatch cut-offs, unclear reporting, and inconsistent data visibility are common causes of SLA failures in 3PL fulfilment.

This guide looks at SLA in 3PL fulfilment from a practical angle. Rather than repeating theory, it focuses on real UK fulfilment standards, realistic benchmarks, and the questions sellers and third-party logistics providers should address before problems arise.

SLA Basics: Definition and Purpose

An SLA in 3PL fulfilment is an operational agreement that sets clear expectations around how fulfilment work is carried out and measured. While a 3PL contract covers commercials, pricing, and liability, the service level agreement focuses on performance and delivery.

A well-defined SLA in a 3PL service level agreement outlines how accuracy, dispatch timing, inventory handling, and returns are tracked on a day-to-day basis. This is especially important for ecommerce fulfilment, where delays or errors quickly impact customer experience.

In the UK, effective SLAs are designed to create clarity rather than enforce penalties. When both the brand and the 3PL understand their responsibilities, issues are resolved faster and fulfilment operations become more predictable and easier to scale.

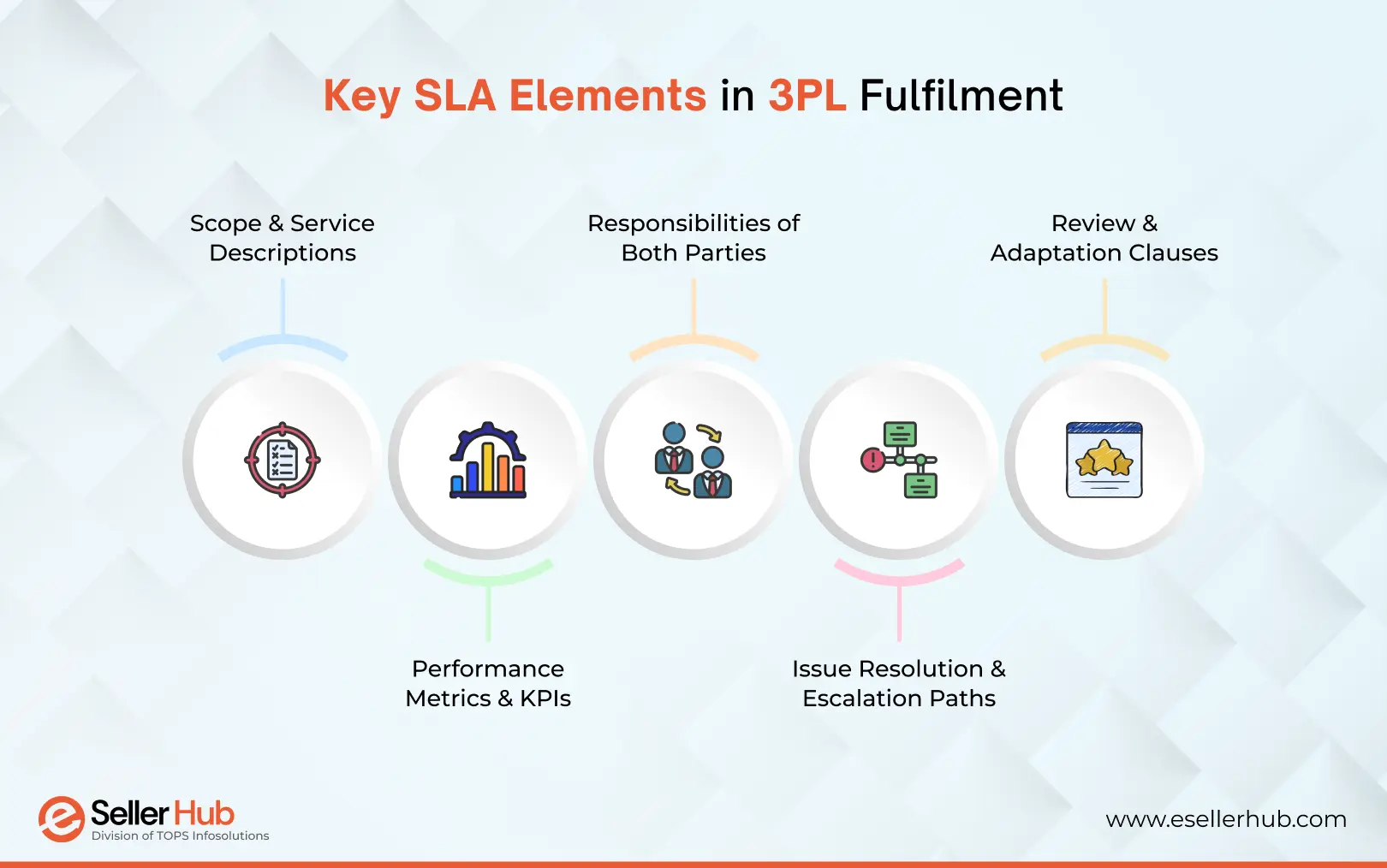

SLA Components That Matter for 3PL Fulfilment

Not all SLA clauses carry the same operational weight. The components below most directly affect fulfilment performance, data visibility, and how quickly issues are resolved.

1. Scope and Service Descriptions

An effective SLA begins with clearly defined scope. This outlines which fulfilment services the 3PL will deliver, including goods-in processing, storage, picking, packing, dispatch, and returns handling. When service descriptions are vague, expectations drift and disputes become far more likely.

2. Performance Metrics and KPIs

Performance metrics sit at the core of any 3PL service level agreement. Common KPIs in an ecommerce fulfilment SLA include pick and pack accuracy, on-time dispatch, inventory accuracy, returns turnaround time, and system availability. These metrics must be clearly defined, consistently measured, and regularly reported to be meaningful.

3. Responsibilities of Both Parties

A service level agreement should clearly separate the responsibilities of the brand and the 3PL, including operational ownership and data visibility. Sellers need to understand what system access they will receive, what data is shared, and how frequently itis updated. Many SLA failures occur because these expectations are assumed rather than documented.

4. Issue Resolution and Escalation Paths

Even well-run fulfilment operations encounter exceptions. Strong SLAs define how issues are raised, who owns them, and how quickly they are escalated. Without a clear escalation path, small issues around dispatch or inventory can quickly turn into wider operational problems.

5. Review and Adaptation Clauses

Fulfilment operations evolve as order volumes grow, sales channels expand, and peak periods increase pressure on warehouses. Regular SLA reviews allow both parties to adjust targets and processes, ensuring the SLA remains relevant rather than static.

UK Fulfilment KPI Benchmarks (Real-World Targets)

Understanding UK 3PL benchmarks helps both sellers and providers set realistic expectations. These benchmarks reflect performance ranges commonly seen across established UK 3PLsK and are intended to guide SLA discussions, not guarantee outcomes.

1. Pick and Pack Accuracy

Measures how often orders are picked and packed correctly without errors. High accuracy reduces returns, re-shipments, and customer complaints, making it one of the most critical 3PL SLA metrics.

2. On-Time Dispatch

Measures how consistently orders are released from the warehouse in line with agreed dispatch deadlines. This KPI is central to most 3PL service level agreements, as delays at dispatch directly impact delivery promises and customer experience.

3. Inventory Accuracy

Shows how closely system stock levels match physical inventory in the warehouse. Poor inventory accuracy leads to overselling, stockouts, and fulfilment delays, especially during peak trading periods.

4. Returns Processing Time

Measures how quickly returned items are received, checked, and updated back into stock. Clear timelines help sellers manage refunds, resale decisions, and customer communication more effectively.

5. System Availability

Refers to the reliability and uptime of warehouse and order management systems. Consistent system availability is essential for accurate reporting, order processing, and ongoing SLA monitoring.

The 3PL Perspective: Why Clarity Must Start at Pick, Pack, and Dispatch

From a 3PL perspective, the SLA defines the operational boundaries of fulfilment. A Clear agreements help providers manage labour, cut-off times, and order flow more effectively across daily operations.

-

Where SLA Language Breaks Down in Practice

Unclear definitions around pick accuracy or dispatch timing are a common cause of SLA disputes. Problems arise when SLA language does not reflect warehouse reality, particularly around carrier handovers and system constraints. This misalignment becomes more visible during peak trading periods.

-

Ownership and Responsibility Gaps

Defining ownership upfront is critical. When responsibility for stock discrepancies or order exceptions is unclear, response times slow and minor issues escalate unnecessarily.

-

Peak Period Handling

Peak trading periods place maximum pressure on UK ecommerce fulfilment services. Strong SLAs explicitly define how performance targets adjust and how escalation processes accelerate during these high-volume windows.

The Seller Perspective: What You Need to Ask Before Signing

For sellers, a 3PL service level agreement is more than a contract formality. It defines how fulfilment performance is measured, what visibility you receive, and how issues are handled when something goes wrong. Understanding the SLA before signing is critical when choosing between third-party logistics providers.

What Sellers Commonly Miss

Many sellers focus on pricing and capacity while overlooking how an SLA is defined. Dispatch timing, data access, and exclusions are often assumed rather than confirmed, leading to issues later.

Key Questions to Ask a 3PL

Before agreeing to a 3PL fulfilment SLA, UK sellers should clarify the following points:

- How exactly is on-time dispatch defined and measured?What qualifies as an exclusion or exception?

- How are peak trading periods handled?

- What reporting and data visibility is provided?

- These questions help set realistic expectations and avoid future disputes.

The Cost of Unclear SLAs

When SLAs lack clarity, sellers face delayed orders, inconsistent reporting, and limited control over fulfilment outcomes. Understanding how to choose a 3PL includes assessing whether the SLA supports transparency, accountability, and long-term growth.

Common SLA Failures in 3PL Fulfilment

Most SLA failures in 3PL fulfilment do not happen because a provider is underperforming. They usually occur because expectations are unclear, poorly defined, or interpreted differently by each side.

1. Dispatch Cut-Off Confusion

Dispatch cut-off times are one of the most common SLA failure points. Sellers may assume same-day dispatch while 3PLs apply different operational rules. Without clear documentation, disputes are inevitable.

2. Responsibility at Carrier Handover

Another frequent failure point is the handover from warehouse to carrier. Many SLAs in 3PL fulfilment stop measuring performance once an order leaves the warehouse, while sellers expect responsibility to extend further. Without clarity at this stage, accountability becomes blurred.

3. Inventory Discrepancy Disputes

Inventory accuracy issues are a recurring source of tension. When system stock does not match physical inventory, sellers may experience overselling or delayed orders. If accuracy standards are not clearly defined,, resolving these disputes becomes difficult.

4. Returns-Related Performance Gaps

Returns processing is often treated as an afterthought in SLAs. When timelines and responsibilities are not specified, sellers face delays in refunds and restocking, which directly affects customer satisfaction and cash flow.

Read More: How Automation Helps UK 3PLs Prevent SLA Failures

How to Use SLA Data to Improve Fulfilment Performance

SLA data should be used to improve fulfilment outcomes, not just report past performance. Regular review helps identify issues early and reduce repeat failures.

-

Track the Right Metrics

SLA tracking works best when key metrics such as on-time dispatch, pick accuracy, inventory accuracy, and returns processing are measured consistently. This gives both sides a clear view of performance trends over time.

-

Identify Root Causes

SLA reports should highlight why targets are missed, not just where. Patterns in the data often point to process gaps, cut-off issues, or system constraints rather than underperformance.

-

Review Performance Regularly

Monthly check-ins and quarterly reviews help sellers and third-party logistics providers stay aligned, adjust expectations, and prepare for peak trading periods.

-

Use Systems for Better Visibility

Accurate SLA reporting depends on reliable warehouse and order management systems. Better visibility supports faster decisions and more effective fulfilment management.

Conclusion

Service level agreements play a critical role in fulfilment performance. When SLAs reflect real operational workflows and are reviewed regularly, they help sellers and 3PLs avoid disputes and maintain consistent service.

For UK ecommerce businesses, the goal is not perfect numbers but realistic expectations around accuracy, dispatch, data visibility, and escalation. SLAs deliver value t when they are used as operational tools that support transparency, accountability, and long-term partnerships rather than static contract clauses.